Ra & RMS:

Calculating Surface Roughness

Choose Your Formula to Calculate Surface Finish

RA

What Does Ra Mean?

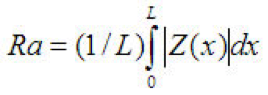

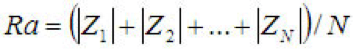

As described in ASME B46.1, Ra is the arithmetic average of the absolute values of the profile height deviations from the mean line, recorded within the evaluation length. Simply put, Ra is the average of a set of individual measurements of a surfaces peaks and valleys. Reveal the Ra formula for more insight.

RMS

What Does RMS Mean?

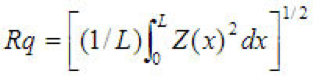

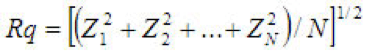

As described in ASME B46.1, RMS is the root mean square average of the profile height deviations from the mean line, recorded within the evaluation length. Reveal the RMS formula for more insight.

What is the difference between Ra and RMS?

Ra and RMS are both representations of surface roughness, but each is calculated differently. Ra is calculated as the Roughness Average of a surfaces measured microscopic peaks and valleys. RMS is calculated as the Root Mean Square of a surfaces measured microscopic peaks and valleys. Each value uses the same individual height measurements of the surfaces peaks and valleys, but uses the measurements in a different formula. The formulas are shown below. One can infer from examination of the formulas, that a single large peak or flaw within the microscopic surface texture will effect (raise) the RMS value more than the Ra value.

The electropolishing process may improve a surface finish by up to 50%. The electropolishing reaction removes material while it improves surface roughness. Because of the material removal, process runtimes are often limited to maintain dimensional tolerances. Limited runtimes result in real world surface roughness improvements from 10 to 35%. Remember, electropolishing improves a surface on the microscopic level. If a material has a texture or surface scratch, electropolishing will only result in a lustrous texture or lustrous scratch. Mechanical polishing is utilized to remove macroscopic texture or blemishes.

Looking for #4, 2B, #8, etc. Stainless Steel Finish Capabilities?

The above finishes are some of many mechanical finishes which are often used in the metal finishing industry. Both the NiDi No. 9012 and previous revisions of ASME BPE specifications include a list that describes various mechanical surface finishes for stainless steel.

Learn more about our Stainless Steel Electropolishing capabilities

Equivalent Ra values for Surface Finish Grade Numbers

Older drawings may use roughness grade numbers to indicate Ra values. The following table is given in ISO 1302:1992.

| Roughness N ISO Grade Numbers |

Roughness values Ra micrometers (µm) |

Roughness values Ra microinches (µin.) |

RMS | CLA (µin.) Center Line Avg. |

Rt Roughness, microns |

|---|---|---|---|---|---|

| N12 | 50 | 2000 | 2200 | 2000 | 200 |

| N11 | 25 | 1000 | 1100 | 1000 | 100 |

| N10 | 12.5 | 500 | 550 | 500 | 50 |

| N9 | 6.3 | 250 | 275 | 250 | 25 |

| N8 | 3.2 | 125 | 137.5 | 125 | 13 |

| N7 | 1.6 | 63 | 64.3 | 63 | 8.0 |

| N6 | 0.8 | 32 | 32.5 | 32 | 4.0 |

| N5 | 0.4 | 16 | 17.6 | 16 | 2.0 |

| N4 | 0.2 | 8 | 8.8 | 8 | 1.2 |

| N3 | 0.1 | 4 | 4.4 | 4 | 0.8 |

| N2 | 0.05 | 2 | 2.2 | 2 | 0.5 |

| N1 | 0.025 | 1 | 1.1 | 1 | 0.3 |